Cannon downriggers offer anglers precise control, enabling presentation of lures at desired depths. These manual systems are reliable, durable, and widely used for effective fishing.

What is a Downrigger and Why Use One?

Downriggers are essential tools for anglers seeking to present bait or lures at specific depths, bypassing the varying levels of fish activity. A downrigger system consists of a boom, base, line, weight, and release mechanism. They counteract the natural buoyancy of the line, allowing controlled descent.

Using a downrigger provides several advantages. It allows anglers to target fish holding at specific depths, especially in large bodies of water. It also minimizes line drag, improving lure action and sensitivity. Cannon downriggers, known for their quality, enable precise depth control and consistent performance, increasing the chances of a successful catch. They are particularly effective for targeting species like salmon and trout.

Cannon Downriggers: A Brand Overview

Cannon has established itself as a leading manufacturer of downrigger systems, renowned for durability and innovative features. For decades, anglers have trusted Cannon for reliable performance in diverse fishing conditions. Their product line includes both manual and electric downriggers, catering to various preferences and budgets.

Cannon downriggers are characterized by robust construction, smooth operation, and precise depth control. They consistently deliver quality and are favored by both recreational and professional fishermen. The brand’s commitment to innovation is evident in features like adjustable boom arms and refined release mechanisms. Cannon continually strives to enhance the angling experience through superior engineering.

Components of a Cannon Manual Downrigger

Cannon manual downriggers consist of a boom, base, line counter, and release mechanism. These key parts work together to precisely deliver lures to the desired fishing depth.

The Downrigger Boom

The downrigger boom is the extending arm of the system, crucial for positioning the line and lure away from the boat. Constructed from durable materials like stainless steel, it provides the necessary reach to spread lines and cover more water.

Its length varies depending on the model and intended fishing application, influencing the maximum distance the weight can be deployed. The boom pivots at the base, allowing for adjustments in horizontal positioning. Cannon booms are designed for strength and stability, even when under significant load with heavy weights and fish. Proper boom maintenance, including occasional cleaning and lubrication, ensures smooth operation and longevity.

Consider the boom’s length when selecting a downrigger, matching it to your boat size and typical fishing scenarios.

The Downrigger Base

The downrigger base is the foundational component, securely mounting the entire system to the boat. Typically constructed from robust materials like stainless steel or reinforced composites, it provides a stable platform for deploying and retrieving weights.

Cannon bases are designed for various mounting options, including rail-mount, flat-mount, and side-mount configurations, ensuring compatibility with different boat types. A key feature is the swivel mechanism, allowing the boom to rotate freely, facilitating line management and preventing tangles.

The base’s stability is paramount for effective downrigging; a secure mount minimizes movement and maximizes control. Regular inspection of the mounting hardware is crucial to ensure continued safety and performance.

The Line Counter

The line counter is a critical feature on Cannon manual downriggers, providing precise depth information as line is deployed. This allows anglers to consistently present lures at the desired fishing depth, crucial for targeting specific species.

Cannon line counters are typically mechanical, driven by the spool rotation. They display the amount of line released in feet or meters, offering a clear visual reading. Accuracy is vital, and regular calibration ensures reliable depth readings.

Understanding the line counter’s functionality is essential for effective downrigging. It enables anglers to maintain consistent depths, adjust presentations, and accurately track lure position in the water column.

The Release Mechanism

The release mechanism is a core component of Cannon manual downriggers, enabling controlled separation of the line from the weight when a fish strikes. This system allows the fish to take the lure without feeling excessive drag, increasing hook-up rates.

Cannon releases typically feature an adjustable tension setting, allowing anglers to customize the force required to trigger the release. Proper adjustment is crucial; too light, and the release fires prematurely, too tight, and fish may throw the lure.

Maintaining the release finger is vital for smooth operation. Regular cleaning and lubrication ensure consistent performance and prevent malfunctions during critical moments on the water.

Setting Up Your Cannon Manual Downrigger

Proper setup involves securely attaching the downrigger line, terminating it correctly, and adding weights with snap assemblies for effective lure presentation.

Attaching the Downrigger Line

Begin by ensuring the downrigger spool is clean and free of any old line remnants. Carefully thread the downrigger line through all guides, starting from the spool and moving towards the boom tip. When spooling, maintain moderate tension to avoid line twist and ensure a tight, even wrap.

Avoid excessive tension, as this can damage the line or the downrigger itself. Fill the spool approximately 80-90% full, leaving some space for line stretch during operation. Secure the line’s initial wraps with a few turns of electrical tape to prevent slippage. Regularly check the line as you spool to confirm proper seating and prevent overrides.

Terminating the Downrigger Line

Proper line termination is crucial for a secure connection to the snap swivel. Begin by wrapping the downrigger line around the spool several times, creating a substantial loop. Then, using a Palomar knot or a similar strong knot designed for braided line, carefully tie the loop to the snap swivel’s eye.

Ensure the knot is tightened securely and inspect it thoroughly for any potential weaknesses or slippage. A poorly tied knot can lead to lost weights and fish. After tying, apply a small amount of line adhesive to the knot for added security and durability. Regularly inspect the termination point for wear and tear.

Attaching Weights and Snap Assemblies

Before attaching weights, confirm the snap swivel is free of any obstructions. Take the snap assembly with insulator and securely attach it to the snap swivel. Ensure a firm connection, as this is a critical link in the downrigger system. Once the snap assembly is in place, you can then attach the desired weight.

Cannon weights come in various sizes and materials; select one appropriate for the fishing conditions. Carefully attach the weight to the snap assembly, verifying it’s locked securely. Always double-check the connection before deploying the downrigger to prevent loss of weight and potential damage.

Using the Snap Assembly with Insulator

The snap assembly with insulator plays a vital role in preventing electrical interference when trolling with lures. It isolates the downrigger line from the weight, minimizing signal disruption to fish finders and other electronic devices. Attach the assembly to the snap swivel, ensuring a secure connection before adding weight.

Proper use involves attaching a Cannon weight to the assembly, then connecting your lure directly to the weight. This setup allows for quick lure changes and efficient fishing. Regularly inspect the insulator for cracks or damage, replacing it if necessary to maintain optimal performance and signal clarity.

Operating Your Cannon Manual Downrigger

Deploying the weight involves releasing line, while retrieval winds it back in. Adjust depth via the line counter, and utilize the release for precise lure presentation.

Deploying the Weight

To effectively deploy the weight with your Cannon manual downrigger, begin by ensuring the release mechanism is set to the ‘free spool’ or ‘open’ position. This allows the weight to descend under its own gravity. Slowly and steadily release line from the reel, monitoring the line counter to track your depth. Maintain a firm, but controlled grip on the line to prevent overruns or tangles.

As the weight sinks, periodically pause to feel for any obstructions or changes in resistance. This can indicate bottom contact or the presence of fish. Continue releasing line until you reach your desired fishing depth, then engage the reel to maintain tension on the line. Remember to consider current and boat drift when determining the appropriate amount of line to deploy.

Retrieving the Weight

When retrieving the weight on your Cannon manual downrigger, begin by disengaging the release mechanism, allowing the weight to be pulled upwards freely. Utilize a smooth, consistent reeling motion, avoiding jerky movements that could cause line twist or shock the system. Monitor the line counter as the weight ascends, noting the depth from which it was retrieved.

Maintain a moderate amount of tension on the line throughout the retrieval process. Once the weight is near the boat, slow down your reeling speed to prevent it from slamming into the downrigger base. Carefully guide the weight and line into the base for a controlled and safe recovery.

Adjusting Depth and Line Release

To adjust depth with a Cannon manual downrigger, simply reel out or retrieve line, observing the line counter for precise depth control. Fine-tune adjustments are crucial for targeting fish at specific levels. The release mechanism allows for controlled line release when a fish strikes.

Ensure the release tension is properly set; too tight, and fish may not trigger the release, too loose, and false releases occur. Experiment with tension settings based on lure type and fish activity. Regularly check the release finger for smooth operation, ensuring accurate and reliable line release when a fish commits.

Maintaining Your Cannon Manual Downrigger

Regular cleaning, lubrication, and line inspection are vital for optimal performance and longevity of your Cannon downrigger. Address issues promptly!

Cleaning and Lubrication

Consistent cleaning and lubrication are paramount to maintaining the smooth operation and extending the lifespan of your Cannon manual downrigger. After each use, especially in saltwater environments, thoroughly rinse the downrigger with fresh water to remove salt, debris, and grime. Pay particular attention to the base, boom, and line release mechanism.

For lubrication, utilize a marine-grade grease specifically designed for fishing equipment. Apply grease to all moving parts, including the reel, release finger pivot points, and boom swivel. Avoid over-greasing, as this can attract dirt and hinder performance. Periodically inspect the downrigger line for any signs of wear or damage, and replace it as needed. Proper maintenance ensures reliable performance season after season.

Line Inspection and Replacement

Regular inspection of your Cannon downrigger line is crucial for safe and effective operation. Before each fishing trip, carefully examine the line for any signs of abrasion, fraying, or weakening. Pay close attention to areas near the release mechanism and where the line contacts the boom or weights. Any visible damage necessitates immediate line replacement.

Choosing the correct replacement line is essential; use a high-quality monofilament or braided line with a breaking strength appropriate for your target species and fishing conditions. When replacing the line, ensure it’s spooled onto the reel correctly and securely terminated. Neglecting line maintenance can lead to line failure, resulting in lost tackle and potentially unsafe situations.

Release Finger Maintenance

The release finger is a critical component of your Cannon manual downrigger, responsible for cleanly releasing the line when a fish strikes. Regular maintenance ensures smooth and reliable operation. After each use, rinse the release finger mechanism with fresh water to remove salt, debris, and corrosion. Inspect the finger for any bends, cracks, or wear.

Lubricate the release finger pivot point with a light silicone-based lubricant to maintain smooth movement. Avoid using petroleum-based lubricants, as they can attract dirt and grime. If the release finger becomes damaged or worn, replace it promptly to prevent missed strikes or line tangles. Proper maintenance extends the life of this vital part.

Troubleshooting Common Issues

Common problems with Cannon downriggers include line twist, release finger malfunctions, and inaccurate depth readings. Addressing these quickly ensures continued fishing success.

Line Twist

Line twist is a frequent issue encountered when using Cannon manual downriggers, impacting lure presentation and potentially causing line failure. This occurs when the line repeatedly spirals during retrieval, creating loops and weakening the overall structure. Several factors contribute to line twist, including the type of line used – monofilament is more prone than braid – and the method of weight retrieval.

To mitigate line twist, consider using a swivel between the downrigger line and the leader. Regularly inspect the line for twists and untwist it manually or by allowing the weight to descend under minimal tension. Avoid rapid, jerky retrieves, opting for a smooth, controlled winding speed. Periodically replacing the downrigger line can also prevent significant build-up of twist, ensuring optimal performance and longevity.

Release Finger Problems

Release finger malfunctions are a common issue with Cannon manual downriggers, hindering the ability to effectively release the line and present lures at the desired depth. These problems often stem from dirt, corrosion, or physical damage to the finger mechanism. A sticky or unresponsive release finger can prevent clean releases, leading to missed strikes or tangled lines.

Regular cleaning and lubrication of the release finger are crucial preventative measures. Inspect the finger for any signs of wear or damage, and replace it if necessary. Ensure the finger moves freely within its housing and that the tension adjustment is properly set. Addressing release finger issues promptly will maintain the downrigger’s functionality and enhance your fishing success.

Depth Counter Inaccuracy

Depth counter inaccuracies on Cannon manual downriggers can compromise precise lure presentation, impacting fishing effectiveness. Several factors contribute to this issue, including worn or damaged counter gears, slippage in the line spooling mechanism, or improper calibration. A misreading depth can lead to lures running too shallow or deep, missing the targeted fish holding zone.

Regularly inspect the counter gears for wear and tear, and lubricate them to ensure smooth operation. Verify the line is spooling correctly and isn’t slipping on the drum. Calibration may be necessary; consult the downrigger’s manual for specific instructions. Addressing depth counter inaccuracies ensures accurate depth control and maximizes angling success.

Advanced Techniques

Stacking downriggers and utilizing diverse weight types enhance fishing strategies. These methods broaden coverage, target varied depths, and increase the likelihood of successful catches.

Stacking Downriggers

Stacking downriggers involves deploying multiple downriggers on slightly different courses, creating a wider spread of presentations. This technique is particularly effective when targeting schools of fish that are spread out horizontally. By staggering the downrigger lines, anglers can cover more water and increase their chances of intercepting fish.

When stacking, it’s crucial to maintain awareness of line angles and potential tangles. Begin with the outermost downriggers set wider apart, gradually narrowing the spacing as you move towards the center. Careful monitoring and adjustments are essential to prevent lines from crossing or interfering with each other during retrieval. Successful stacking requires precision and a thorough understanding of how fish react to multiple presentations.

Using Different Weight Types

Cannon downriggers accommodate various weight types, allowing anglers to adapt to different fishing scenarios and target species. Traditional lead weights are cost-effective and provide excellent depth control. However, alternatives like tungsten weights offer increased density, enabling deeper presentations with smaller profiles. These are beneficial when fishing pressured waters or targeting line-shy fish.

The choice of weight also depends on current and bottom conditions. Heavier weights are necessary in strong currents to maintain line angle and prevent excessive drag. Consider using streamlined weights to minimize resistance and improve lure action. Experimenting with different weight shapes and sizes is key to optimizing your presentation and maximizing your success on the water.

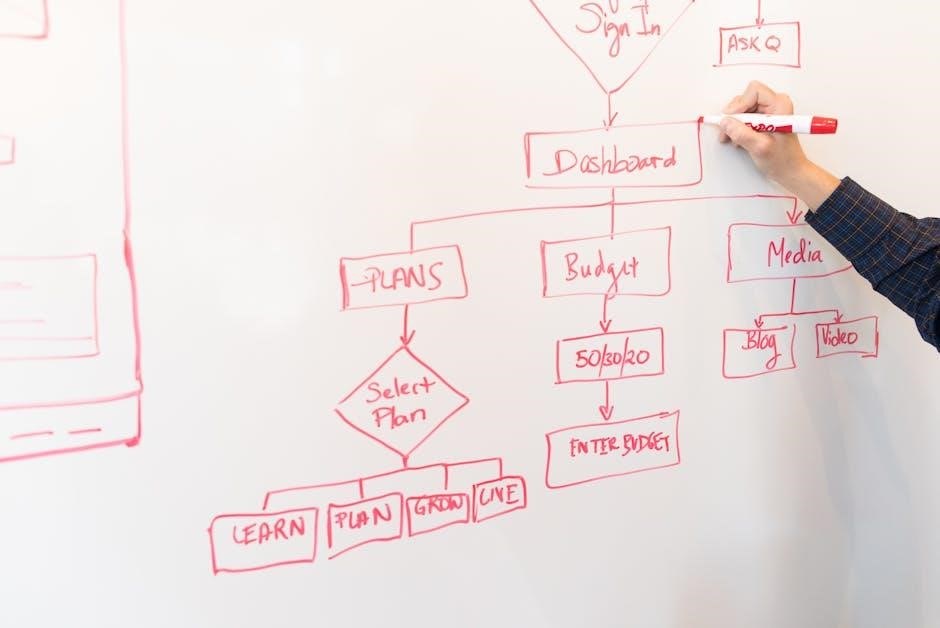

Connecting to a Network

Cannon downriggers with Bluetooth can connect to a network, designating one as the Master; Connecting a Cannon transducer disrupts existing networks if not done correctly.

Cannon Transducer and Bluetooth

Cannon downriggers equipped with Bluetooth capability unlock advanced networking features, enhancing the angling experience. Integrating a Cannon transducer into a Bluetooth-enabled downrigger system establishes a central hub for data transmission and control. This allows for seamless communication between multiple downriggers, creating a synchronized and efficient fishing setup.

When a Cannon transducer is connected, one downrigger automatically assumes the role of the Master downrigger within the network. It’s crucial to understand that introducing a transducer to any downrigger except an existing Master will disrupt the established network configuration. Careful consideration is needed to avoid unintended consequences during setup and ensure optimal performance of the networked system.

Master Downrigger Considerations

Establishing a Master downrigger within a Cannon networked system is vital for seamless operation. The Master unit serves as the central control point, coordinating data from all connected downriggers via Bluetooth. Connecting a Cannon transducer to a Bluetooth-enabled downrigger automatically designates it as the Master.

However, introducing a transducer to any downrigger other than an existing Master will disrupt the network. Therefore, careful planning is essential. If a Master already exists, avoid connecting the transducer to any other unit. Prioritize maintaining a stable Master to ensure consistent data flow and synchronized control across all Cannon downriggers in the network.