Understanding Utility Pole Guide Wires

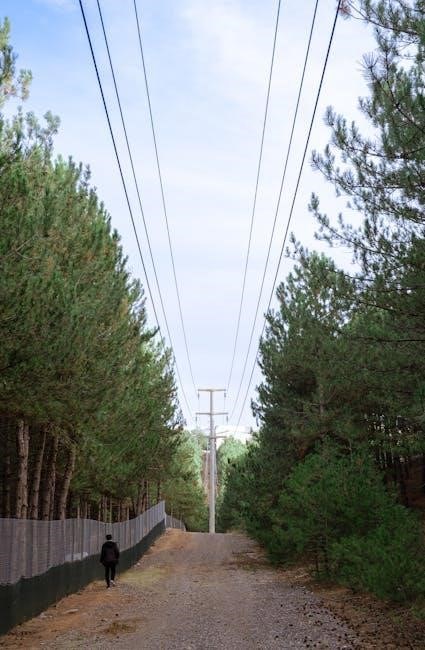

Utility pole guide wires are crucial components, often overlooked, providing essential stability to tall structures like utility and communication poles.

These wires, extending from near the top of the pole to anchor points on the ground, counteract forces from wind and the weight of carried equipment.

They are vital for preventing pole failure and ensuring continuous service delivery, especially during adverse weather conditions, safeguarding public safety and infrastructure.

What are Utility Pole Guide Wires?

Utility pole guide wires, frequently constructed from high-tensile strength materials, are tensioned cables extending diagonally from a utility pole to ground anchors. They aren’t directly involved in carrying electrical current; instead, their primary function is structural support. These wires act as stabilizers, resisting lateral forces exerted by wind, ice accumulation, or even the dynamic load created by repairs and maintenance activities performed on the pole itself.

Typically, you’ll observe two or three guide wires per pole, strategically positioned to provide balanced support. They are essential for poles supporting a significant load, such as those carrying multiple transformers, communication lines, or street lighting fixtures. Without these wires, the pole would be far more susceptible to bending, swaying, or even complete collapse, potentially leading to power outages and safety hazards. Their presence is a key element in maintaining the integrity of the utility infrastructure.

Purpose of Guide Wires: Stability and Support

The core purpose of utility pole guide wires is to dramatically enhance the stability and structural integrity of utility poles. They counteract forces that could compromise the pole’s upright position, preventing potential failures. Wind loading is a primary concern; guide wires distribute these forces to the ground, reducing stress on the pole itself.

Beyond wind, guide wires provide crucial support against the weight of the equipment mounted on the pole – transformers, cabling, and lighting fixtures all contribute to downward and lateral pressure. They also stabilize the pole during maintenance activities, like lineman work, ensuring a safe working environment. Essentially, these wires transform a potentially unstable structure into a robust and reliable component of the power and communication network, minimizing service disruptions and enhancing overall safety.

Types of Guide Wire Materials

Several materials are employed in the construction of utility pole guide wires, each offering distinct advantages based on cost, strength, and environmental considerations. Galvanized steel is a common choice due to its affordability and reasonable tensile strength, providing good corrosion resistance for many applications. However, it’s susceptible to rust over time, requiring periodic maintenance.

Stainless steel guide wires represent a premium option, offering superior corrosion resistance and a longer lifespan, particularly in harsh environments. High-strength alloy guide wires, often incorporating materials like aluminum alloys, provide an excellent strength-to-weight ratio, reducing the load on the pole and anchors. The selection of material depends on factors like local climate, soil conditions, and the specific load requirements of the utility pole, balancing performance with budgetary constraints.

Galvanized Steel Guide Wires

Galvanized steel guide wires are a widely utilized option due to their balance of cost-effectiveness and adequate performance characteristics. The galvanization process, applying a protective zinc coating, provides a degree of corrosion resistance, extending the wire’s lifespan compared to bare steel. However, this protection isn’t absolute; the zinc coating will eventually degrade, leading to rust, especially in environments with high salinity or acidic conditions.

Regular inspections are crucial for galvanized steel wires to identify and address corrosion before it compromises the wire’s strength. These wires typically offer sufficient tensile strength for many standard utility pole applications, making them a practical choice where extreme durability isn’t paramount. Their widespread availability and relatively low cost contribute to their continued popularity in utility infrastructure projects.

Stainless Steel Guide Wires

Stainless steel guide wires represent a significant upgrade in durability and corrosion resistance compared to galvanized steel options. The inherent properties of stainless steel alloys, particularly those containing chromium, form a passive layer that protects against rust and environmental degradation. This makes them ideal for harsh environments, such as coastal areas or industrial zones with corrosive pollutants.

While more expensive upfront, stainless steel wires offer a longer service life and reduced maintenance requirements, potentially offsetting the initial cost. Different grades of stainless steel are available, offering varying levels of strength and corrosion resistance to suit specific application needs. They are a preferred choice when long-term reliability and minimal upkeep are critical factors in utility pole stability and safety.

High-Strength Alloy Guide Wires

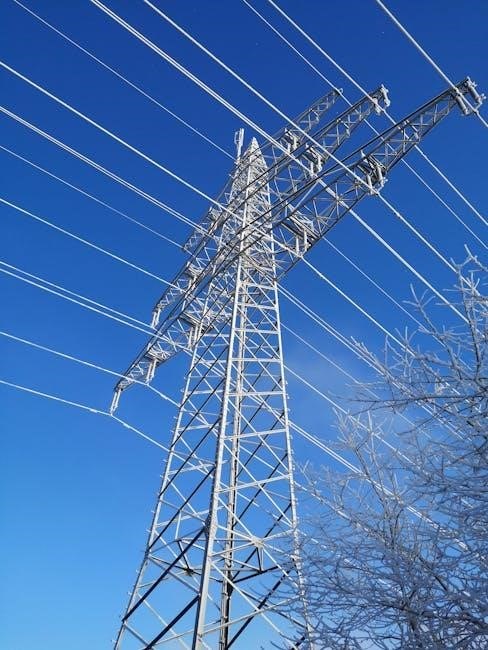

High-strength alloy guide wires represent the pinnacle of performance in utility pole support systems, engineered for exceptional tensile strength and durability. These wires are typically composed of specialized steel alloys, often incorporating elements like vanadium or molybdenum, to enhance their mechanical properties beyond those of standard steel.

This results in a superior strength-to-weight ratio, allowing for reduced wire diameter while maintaining equivalent or greater load-bearing capacity. They are particularly valuable in situations demanding maximum stability, such as supporting taller poles or those carrying heavier equipment loads. While representing the highest initial investment, high-strength alloys offer extended service life, minimized sag, and enhanced resistance to deformation, ultimately contributing to long-term cost savings and improved infrastructure reliability.

Guide Wire Installation and Configuration

Proper installation of guide wires is paramount for effective pole stabilization, demanding precise anchor placement and careful tensioning to distribute loads evenly.

Correct configuration ensures optimal support.

Proper Anchor Placement for Guide Wires

Strategic anchor placement is fundamental to the effectiveness of utility pole guide wires, directly influencing the pole’s stability and resistance to external forces. Anchors must be situated at a sufficient distance from the pole base, typically following a recommended ratio based on pole height, to achieve the optimal angle of departure.

Soil conditions play a critical role; anchors require firm, stable ground to prevent pull-out under tension. Concrete footings or driven ground rods are commonly employed to ensure secure anchorage, particularly in areas with loose or sandy soil. Avoiding underground utilities is paramount during anchor installation, necessitating thorough site surveys and adherence to local regulations.

Furthermore, anchor points should be positioned to distribute tension evenly around the pole, preventing undue stress on any single side. Consideration must also be given to accessibility for future inspections and maintenance, ensuring clear pathways for personnel and equipment. Improper anchor placement compromises the entire guide wire system, potentially leading to pole instability and safety hazards.

Tensioning Guide Wires: Ensuring Optimal Support

Achieving correct tension in guide wires is critical for providing the necessary support to utility poles, balancing external loads and maintaining structural integrity. Tensioning isn’t simply about pulling the wires tight; it requires a precise approach using calibrated tensioning devices, like turnbuckles, to apply the recommended force specified by engineering standards.

Uneven tension between guide wires can induce twisting or bending stresses on the pole, compromising its stability. Regular monitoring and adjustment of tension are essential, as wires can stretch over time due to environmental factors and load fluctuations. Proper tensioning minimizes sway, reduces the risk of pole failure during storms, and extends the lifespan of the entire system.

Qualified personnel should perform tensioning, adhering to safety protocols and utilizing appropriate personal protective equipment. Over-tensioning can damage the wires or pole, while insufficient tension provides inadequate support, creating a potential hazard.

Angle of Departure: Impact on Stability

The angle at which guide wires depart from the utility pole significantly influences the stability and effectiveness of the support system. A shallower angle provides greater horizontal restraint, resisting lateral forces like wind, but requires longer anchor lengths. Conversely, steeper angles offer less horizontal restraint but demand shorter anchor spans.

Optimal angles, typically between 45 and 60 degrees, strike a balance between these factors, maximizing stability without excessive land usage. Deviations from these recommended angles can reduce the wire’s ability to counteract forces effectively, potentially leading to pole movement or even failure.

Consistent angles across all guide wires are crucial for even load distribution. Careful consideration of terrain, surrounding obstacles, and soil conditions is vital when determining the appropriate departure angle for each wire, ensuring long-term structural integrity and safety.

Safety Considerations Regarding Guide Wires

Guide wires pose significant safety risks; maintaining adequate clearance is paramount to prevent accidental contact and potential electrocution or serious injury.

Hazards of Contact with Guide Wires

Contact with utility pole guide wires presents a multitude of dangers, primarily due to the potential for electrical conductivity. While the guide wires themselves aren’t typically energized, they are often closely associated with, and can become inadvertently connected to, energized utility lines.

Direct contact, even with a seemingly non-energized wire, can be lethal if the wire has come into contact with a power line due to pole sway, damage, or environmental factors. Furthermore, even non-electrical hazards exist; a sudden impact with a taut guide wire, such as from a vehicle collision, can cause significant injury to occupants.

The wires are under high tension, and breakage can result in a whipping action, creating a projectile hazard. It’s crucial to remember that these wires are not designed for climbing or any form of physical interaction. Always treat all utility pole components as potentially dangerous and maintain a safe distance.

Maintaining Safe Clearance Around Guide Wires

Establishing and maintaining adequate clearance around utility pole guide wires is paramount for public safety. This involves several key practices, beginning with awareness of their presence and potential hazards. Vegetation management is crucial; trees and shrubs should be regularly trimmed to prevent contact with the wires, eliminating potential pathways for electricity.

Parking vehicles within the designated safety zone around poles – typically marked or implied by the wire anchor points – should be strictly avoided. Construction and excavation activities near poles require careful planning and adherence to safety regulations, including calling before you dig to identify underground utilities and wire locations.

Educating the public about the dangers of guide wires and the importance of maintaining distance is also vital; Always assume wires are energized and report any concerns to the utility company immediately.

Reporting Damaged or Sagging Guide Wires

Promptly reporting damaged or sagging guide wires is a critical safety measure. These conditions indicate a compromised support system, potentially leading to pole failure and hazardous situations. Any visible signs of damage – breaks, fraying, corrosion, or significant slack – should be reported immediately to the local utility company or emergency services.

When reporting, provide a precise location, including street address, pole number (if visible), and a detailed description of the issue. Avoid approaching or touching the damaged wire; maintain a safe distance. A vehicle collision with a guide wire, even without apparent wire damage, warrants immediate reporting.

Utility companies prioritize these reports, dispatching crews to assess and repair the situation swiftly. Your vigilance can prevent accidents and ensure the continued reliability of essential utility services.

Guide Wire Maintenance and Inspection

Regular inspection and maintenance of guide wires are essential for sustained utility pole stability and safety, preventing potential failures and service disruptions.

Regular Visual Inspections for Corrosion

Consistent visual checks are paramount in identifying corrosion on utility pole guide wires, a primary cause of weakening and potential failure. Inspections should focus on areas where the wire connects to the pole and ground anchors, as these are particularly vulnerable to environmental exposure.

Look for signs of rust, pitting, or significant discoloration, indicating a breakdown of the protective coating. Pay close attention to areas where the wire passes through insulators or comes into contact with hardware. Document any observed corrosion with photographs and detailed notes, including the location and severity.

Early detection allows for timely intervention, preventing minor corrosion from escalating into a critical structural issue. Regular inspections, ideally conducted annually or after severe weather events, contribute significantly to maintaining the integrity and safety of the utility pole system. Remember, proactive monitoring is key to avoiding costly repairs and service interruptions.

Checking Guide Wire Tension

Maintaining proper tension in utility pole guide wires is critical for their effectiveness; too little tension compromises stability, while excessive tension can overstress the pole and wire itself. Tension checks should be performed by qualified personnel using appropriate tools, such as tension meters or dynamometers.

Observe for visible sag in the wires, which indicates a loss of tension. Compare the tension readings to the manufacturer’s specifications or established baseline measurements for that specific pole and wire configuration. Document all readings meticulously, noting any deviations from the acceptable range.

Adjustments to tension should only be made by trained professionals, ensuring a balanced load distribution among all guide wires. Regular tension checks, alongside visual inspections, contribute to a proactive maintenance program, maximizing the lifespan and reliability of the utility pole infrastructure and preventing potential hazards.

Professional Inspections and Repairs

Comprehensive guide wire inspections should be conducted periodically by qualified utility professionals. These inspections go beyond visual checks, utilizing specialized equipment to assess wire tension, corrosion levels, and anchor point integrity. Detailed reports documenting findings are essential for tracking maintenance needs and ensuring long-term reliability.

Repairs, including wire replacement, anchor reinforcement, or tension adjustments, must be performed by certified technicians adhering to strict safety protocols. Damaged or corroded wires should be replaced promptly to prevent failure. Anchor points exhibiting signs of weakness require immediate attention, potentially involving soil stabilization or complete replacement.

Regular professional maintenance minimizes the risk of unexpected outages, enhances public safety, and extends the service life of utility poles and associated infrastructure. Proactive repairs are significantly more cost-effective than reactive responses to failures.

Incidents Involving Guide Wires

Collisions with guide wires, like the SUV incident at Laredo and Crosstown, demonstrate potential hazards. Breaks pose risks, causing pole instability and service disruptions.

Vehicle Collisions with Guide Wires

Vehicle collisions with utility pole guide wires, while seemingly uncommon, represent a significant safety concern and can lead to substantial damage. The incident reported at the intersection of Laredo and Crosstown, involving a sport utility vehicle striking a guide wire after running a red light, exemplifies this risk.

These collisions often occur due to driver error, poor visibility, or challenging road conditions. The impact can cause the guide wire to snap, immediately compromising the stability of the utility pole itself. This, in turn, can lead to the pole tilting or even collapsing, potentially bringing down power lines or communication cables.

Such events not only create immediate hazards for motorists and pedestrians but also result in service outages for nearby customers. The force of the impact can also damage the vehicle involved, potentially causing injuries to the occupants. Proper signage and public awareness campaigns are crucial in mitigating these incidents and ensuring the safety of all road users.

Guide Wire Breaks and Associated Risks

Guide wire breaks present a range of serious hazards, extending beyond the immediate failure of a single wire. When a guide wire snaps, the utility pole loses a critical element of its structural support system, increasing its vulnerability to collapse, particularly under stress from wind or ice loading.

This sudden loss of stability can cause the pole to tilt, potentially bringing down the lines it supports – power, communication, or both. Downed power lines pose an electrocution risk to anyone who comes into contact with them, and can also spark fires. Broken wires themselves can become projectiles, causing damage to surrounding property or injury to passersby.

Furthermore, the disruption of utility services impacts residents and businesses, leading to power outages and communication disruptions. Prompt reporting of any observed sagging or broken guide wires is essential to minimize these risks and ensure swift repair by qualified professionals, safeguarding public safety and infrastructure reliability.