PVC Electrical Conduit Installation Guide

Navigating PVC conduit installations requires understanding diverse types – PVC-U, PVC-M, and CPVC – alongside crucial factors like corrosion resistance and UV exposure․

Detailed guides, often available as PDF resources, emphasize proper selection for wet or corrosive environments, ensuring longevity and safety․

Understanding PVC Conduit Types

PVC conduit isn’t a monolithic entity; several types cater to specific installation needs․ Primarily, we encounter PVC-U (Unplasticized Polyvinyl Chloride), the most prevalent form, known for its rigidity and broad applicability․ It’s ideal for general electrical wiring and is frequently detailed in PVC electrical conduit installation guide PDFs․

Then there’s PVC-M (Modified PVC), offering enhanced impact resistance, particularly valuable in colder climates or areas prone to physical stress․ CPVC (Chlorinated Polyvinyl Chloride) stands apart with superior temperature resistance, making it suitable for specialized applications․ Understanding these distinctions is crucial, as PDF guides often specify which type is appropriate for different environments and electrical loads․

Furthermore, variations exist based on wall thickness – Schedule 40 and Schedule 80 – impacting strength and pressure handling capabilities․ The choice hinges on factors like burial depth, potential impact risks, and local electrical codes․ Comprehensive installation guides, often in PDF format, meticulously outline these considerations, ensuring compliance and a safe, durable installation․ Always consult relevant PDF documentation for detailed specifications and application recommendations․

Schedule 40 vs․ Schedule 80 PVC Conduit

Schedule 40 and Schedule 80 PVC conduit represent differing wall thicknesses, directly impacting strength and application suitability․ Schedule 40, the more common option, provides adequate protection for general electrical installations, often detailed extensively in PVC electrical conduit installation guide PDFs․ It’s cost-effective and suitable for most indoor and above-ground outdoor applications․

Schedule 80, boasting a thicker wall, offers significantly increased impact resistance and pressure-handling capacity․ This makes it ideal for direct burial, industrial environments, or locations where physical damage is a concern․ PDF guides frequently emphasize Schedule 80’s necessity when conduit is exposed to heavy traffic or potential abuse․

The numerical designation (“40” or “80”) refers to a pressure rating, not the actual wall thickness․ Choosing between the two requires careful consideration of local electrical codes, environmental factors, and potential hazards․ Detailed charts within installation guides (available as PDF downloads) illustrate load-bearing capacities and appropriate applications․ Always prioritize safety and compliance by referencing a comprehensive PDF resource․

PVC Conduit Applications: Indoor vs․ Outdoor

PVC conduit’s versatility allows for widespread use in both indoor and outdoor electrical systems, though application specifics differ․ Indoor applications, frequently detailed in PVC electrical conduit installation guide PDFs, benefit from PVC’s non-conductivity and resistance to corrosion, making it ideal for commercial buildings, residential wiring, and industrial facilities․

Outdoor installations demand consideration of UV exposure and temperature fluctuations․ While standard PVC can degrade under prolonged sunlight, UV-resistant formulations are readily available and recommended – information readily found in comprehensive PDF guides․ Direct burial applications, also covered extensively in these PDF resources, necessitate Schedule 80 conduit for enhanced protection against soil pressure and potential damage․

PDF installation guides emphasize the importance of proper support and spacing for outdoor runs to prevent sagging and stress․ Furthermore, PVC’s resistance to corrosive elements makes it a superior choice for agricultural settings or coastal environments․ Always consult a detailed PDF guide to ensure compliance with local codes and optimal performance․

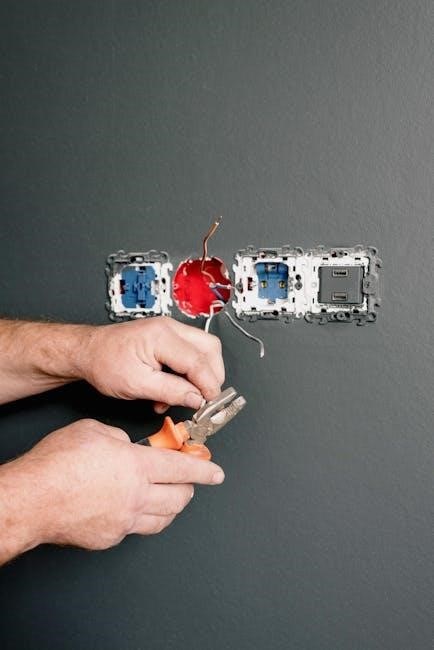

Tools Required for PVC Conduit Installation

Successful PVC conduit installation hinges on having the correct tools, often outlined in detailed PVC electrical conduit installation guide PDFs․ Essential tools include a PVC cutter – either a saw, ratchet cutter, or rotary cutter – for clean, precise cuts․ A reamer and deburring tool are crucial for removing burrs and ensuring smooth connections, preventing solvent cement issues․

PDF guides consistently recommend a measuring tape, marker, and level for accurate layout and alignment․ For bending, a hot box or cold bending jig is necessary, depending on the desired bend radius and conduit size․ A solvent cement applicator and gloves are vital for safe and effective joining of conduit sections․

Furthermore, a drill with appropriate bits is needed for mounting conduit supports․ Many PDF resources also suggest having a conduit bender, wire puller, and safety glasses readily available․ Consulting a comprehensive PDF installation guide ensures you have a complete toolkit for a professional and code-compliant installation․

Cutting PVC Conduit: Methods and Best Practices

Achieving clean, square cuts is paramount in PVC conduit installation, as detailed in most PVC electrical conduit installation guide PDFs․ Several methods exist: using a PVC saw (a specialized hand saw), a ratchet cutter (providing a clean, quick cut), or a rotary cutter (suitable for smaller conduit sizes)․ Regardless of the method, maintaining a 90-degree angle is critical for proper fitting alignment․

PDF guides emphasize the importance of using a deburring tool immediately after cutting to remove any internal or external burrs․ These burrs can impede solvent cement bonding and create stress points․ Always measure accurately before cutting, accounting for fitting insertion depths․ Avoid using abrasive cutting tools that can create excessive heat or leave rough edges․

Proper technique, as illustrated in PDF resources, involves applying even pressure during cutting and supporting the conduit to prevent cracking․ Regularly inspect cutting tools for sharpness to ensure clean cuts and minimize the risk of damage․ Following these best practices guarantees a secure and reliable conduit system․

Reaming and Deburring PVC Conduit

Essential steps often highlighted in a comprehensive PVC electrical conduit installation guide PDF are reaming and deburring․ Cutting PVC conduit, even with specialized tools, inevitably leaves burrs – both inside and outside the pipe; These imperfections significantly hinder proper solvent cement adhesion and can create stress concentrations, potentially leading to joint failure․

Reaming, using a reaming tool specifically designed for PVC, removes internal burrs and ensures a smooth surface for cement bonding․ Deburring addresses external burrs, preventing damage to the cement applicator and ensuring a flush fit with fittings․ PDF guides consistently stress that neglecting these steps compromises the integrity of the entire conduit run․

Thoroughness is key; a PDF will often show detailed illustrations of the process․ Inspect the conduit after each step to confirm complete burr removal․ Proper reaming and deburring contribute significantly to a long-lasting, reliable, and code-compliant PVC conduit installation, minimizing the risk of future issues and ensuring safety․

PVC Conduit Fittings: Types and Selection

A detailed PVC electrical conduit installation guide PDF will dedicate significant space to fittings, as correct selection is paramount․ Beyond simple straight connectors, a wide array exists, including elbows (90 and 45-degree), tees, crosses, couplings, and bell/spigot fittings for solvent welding․ Adapters are crucial for transitioning between PVC and other materials like metal conduit․

Choosing the right fitting depends on the application – direct burial requires specific fittings rated for that purpose․ Schedule 40 vs․ Schedule 80 considerations extend to fittings; they must match the conduit’s schedule․ PDF guides emphasize verifying fittings are UL Listed or meet relevant standards for safety and code compliance․

Threaded fittings offer a mechanical connection option, but solvent-welded fittings generally provide a more permanent and watertight seal․ The PDF will illustrate proper fitting identification and compatibility charts, ensuring a secure and reliable electrical system․ Careful selection prevents leaks, maintains grounding continuity, and ensures long-term performance․

Joining PVC Conduit: Solvent Cement Welding

A comprehensive PVC electrical conduit installation guide PDF will detail solvent cement welding as the primary joining method․ This process chemically fuses the PVC conduit and fittings, creating a robust, watertight seal․ It’s crucial to use the correct cement type – specific formulations exist for different schedules (40/80) and temperatures․

Preparation is key: both surfaces must be clean, dry, and free of debris․ A primer is typically applied first to soften the PVC, enhancing the bond․ The PDF will illustrate proper application techniques – a generous, even coat of cement, followed by a quick insertion and quarter-turn twist to distribute the solvent․

Working time is limited, so efficiency is vital․ Avoid excessive cement, which can create internal obstructions․ Allow sufficient curing time – as specified by the cement manufacturer – before applying any stress to the joint․ The guide will emphasize safety precautions, including adequate ventilation due to solvent fumes․

Solvent Cement Application Techniques

A detailed PVC electrical conduit installation guide PDF stresses precise solvent cement application for reliable joints․ Begin by ensuring both conduit and fitting surfaces are thoroughly cleaned and dried – any contaminants impede bonding․ The primer, applied first, softens the PVC, creating a receptive surface for the cement․ Use a dedicated applicator, avoiding contamination of the cement container․

Apply cement generously and evenly around the conduit’s outer circumference and to the fitting’s inner hub․ Work quickly, as the cement sets rapidly․ Immediately insert the conduit into the fitting with a slight twisting motion (approximately ¼ turn) to distribute the cement fully․ Avoid excessive twisting or movement, which can disrupt the bond․

Hold the joint firmly for 30-60 seconds to allow initial set․ The PDF will outline specific curing times based on temperature and cement type․ Proper ventilation is paramount due to solvent fumes; always work in a well-ventilated area and wear appropriate respiratory protection․

Proper PVC Conduit Support and Spacing

A comprehensive PVC electrical conduit installation guide PDF details crucial support and spacing requirements to prevent sagging, stress, and potential failure․ Supports must be installed at intervals specified by code and the conduit’s diameter – typically, every 10 feet for Schedule 40 and 8 feet for thinner walls․

Utilize appropriate supports like straps, clamps, or hangers designed for PVC conduit․ Avoid direct contact between metal supports and PVC to prevent galvanic corrosion; use insulating bushings or sleeves․ The PDF will illustrate correct support placement, particularly around bends, tees, and other fittings, where additional support is often needed․

Spacing considerations also depend on conduit fill and environmental factors․ For direct burial applications, closer spacing is essential to maintain structural integrity․ Ensure supports are securely anchored to building structures and can withstand the conduit’s weight, including the conductors within․ Adhering to these guidelines ensures a safe and durable installation․

Bending PVC Conduit: Hot Box vs․ Cold Bending

A detailed PVC electrical conduit installation guide PDF outlines two primary bending methods: hot box bending and cold bending․ Cold bending, suitable for smaller diameter conduit, involves using a conduit bender to create smooth, controlled bends without external heat․ This method requires physical strength and proper technique to avoid cracking or kinking․

Hot box bending, ideal for larger diameters or tighter radii, utilizes a heating element to make the PVC pliable․ The PDF emphasizes precise temperature control – overheating can weaken the conduit, while insufficient heat prevents proper forming․ Specialized hot boxes ensure even heating and consistent results․

Safety is paramount with hot bending; wear heat-resistant gloves and eye protection․ Regardless of the method, always allow the conduit to cool completely before handling or joining․ The guide will illustrate proper bending techniques and radius limitations for both methods, ensuring code compliance and a professional finish․

Direct Burial of PVC Conduit: Considerations

A comprehensive PVC electrical conduit installation guide PDF details crucial considerations for direct burial applications․ While PVC offers excellent corrosion resistance, proper installation is vital for long-term reliability․ The PDF stresses the importance of backfilling with appropriate materials – avoid rocks or sharp objects that could damage the conduit․

Depth requirements vary based on local electrical codes and soil conditions; the guide provides typical depth recommendations․ Furthermore, it highlights the need for adequate warning tape placed above the conduit to prevent accidental damage during future excavation․ Direct burial applications often necessitate a greater Schedule number (Schedule 80) for increased crush resistance․

Grounding and bonding are critical when directly burying PVC, as PVC itself doesn’t provide a grounding path․ The PDF outlines methods for incorporating a separate grounding conductor within the conduit system․ Always consult local regulations and the PDF’s detailed specifications to ensure a safe and compliant installation․

Grounding and Bonding with PVC Conduit

A detailed PVC electrical conduit installation guide PDF emphasizes that PVC conduit, being non-conductive, requires specific grounding and bonding procedures․ Unlike metal conduit, PVC doesn’t inherently provide a path to ground, necessitating supplementary measures for electrical safety․

The PDF outlines the necessity of utilizing a separate grounding conductor installed within the PVC conduit system․ This conductor, typically copper or aluminum, must be securely bonded to the equipment being served and to the electrical service panel․ Proper bonding minimizes the risk of electrical shock and ensures effective fault current paths․

Specific techniques for bonding are detailed in the PDF, including the use of approved bonding bushings and connectors․ It also stresses the importance of adhering to all applicable electrical codes and standards․ Ignoring proper grounding and bonding with PVC conduit can create a significant safety hazard, making the PDF’s guidance essential for compliant installations․

PVC Conduit in Corrosive Environments

A comprehensive PVC electrical conduit installation guide PDF highlights PVC’s superior resistance to corrosion compared to metallic conduits, making it ideal for challenging environments․ The PDF details applications where PVC excels, such as wastewater treatment plants, chemical processing facilities, and coastal areas exposed to salt spray․

However, the PDF clarifies that not all PVC formulations are equal․ It distinguishes between PVC-U, PVC-M, and CPVC, explaining how their chemical compositions affect their resistance to specific corrosive agents․ For particularly harsh conditions, the PDF recommends CPVC (Chlorinated Polyvinyl Chloride) due to its enhanced chemical resistance․

Installation best practices outlined in the PDF include selecting the appropriate PVC compound for the anticipated chemical exposure, ensuring proper jointing to prevent ingress of corrosive substances, and utilizing PVC-coated metal conduits for added protection․ The PDF also emphasizes regular inspection to identify and address any signs of degradation, ensuring long-term reliability in corrosive settings․

Inspection and Safety Precautions for PVC Conduit Installation

A detailed PVC electrical conduit installation guide PDF stresses the importance of rigorous inspection throughout the process․ Before installation, the PDF advises verifying that all PVC conduit and fittings are free from defects, cracks, or damage․ During installation, it emphasizes checking the proper alignment and support of the conduit runs, adhering to specified spacing guidelines․

Safety is paramount, as the PDF outlines․ It mandates the use of appropriate personal protective equipment (PPE), including safety glasses, gloves, and respirators when cutting or solvent cementing PVC․ The PDF warns against inhaling solvent cement fumes and stresses the need for adequate ventilation․

Post-installation inspection, detailed in the PDF, includes verifying the integrity of all joints, ensuring proper grounding and bonding, and confirming that the conduit is adequately protected from physical damage․ The PDF also highlights the importance of following all applicable electrical codes and regulations, ensuring a safe and compliant installation․